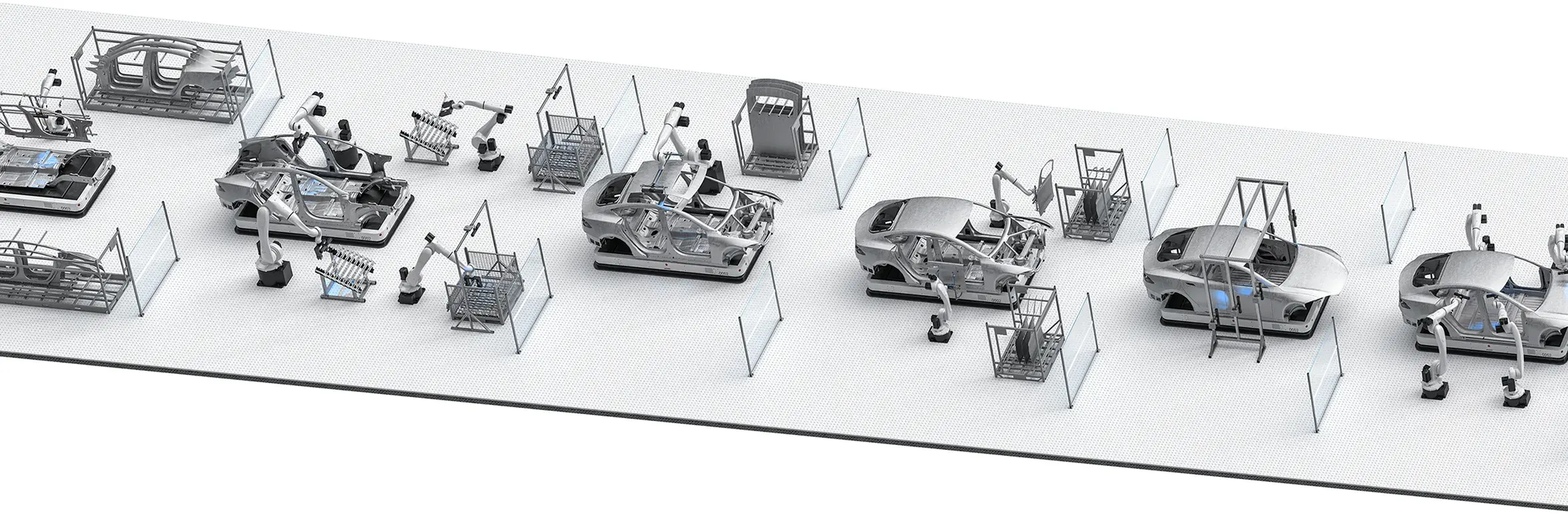

Car Manufacturing Automation

with 3D Scanners & Vision Guided Software

3D Sensors and Vision Guided Software precision-engineered for the world’s most demanding production lines.

Higher Throughput on Moving Lines

Eliminate automotive production bottlenecks with real-time 3D Vision that performs inspections and guides automation at full line speed.

Quality at Submillimeter Precision

High-accuracy 3D data that enables precise part localization, gap/flushness inspection, and fastener verification, dramatically improving first-pass yield.

Performance in Harsh Factory Environment

3D Vision engineered to ignore welding arcs, direct sunlight, and the challenges of shiny metals and hot surfaces, ensuring 24/7 uptime.

.png)

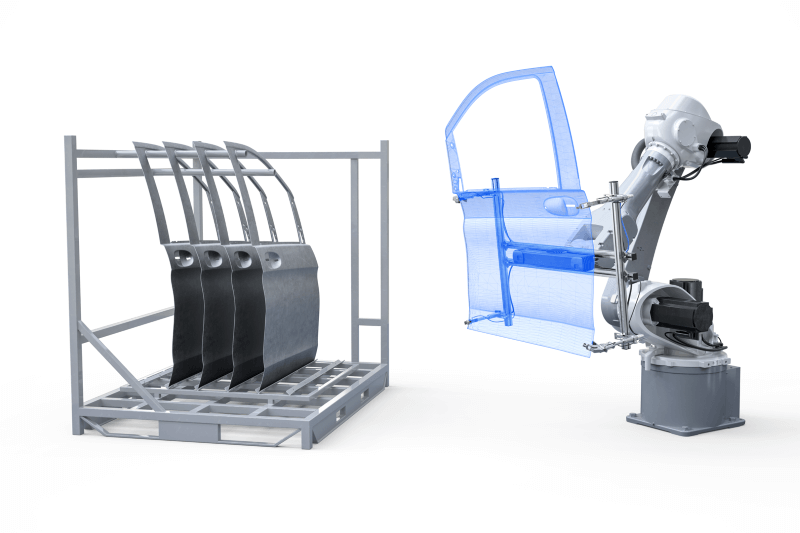

Master Handling of Complex Parts

Eliminate occlusions and blind spots on challenging automotive parts. Thin, reflective, or self-occluding. Ensure consistent pick-and-place success rates.

Virtual Walkthrough

Automotive Automation with 3D Vision & Robotics Software

Click through Stamping, Gigapress, Bodyshop, General Assembly, Powertrain and Tier 1 to see how Photoneo 3D sensors and vision-guided software solve real production challenges at every step.

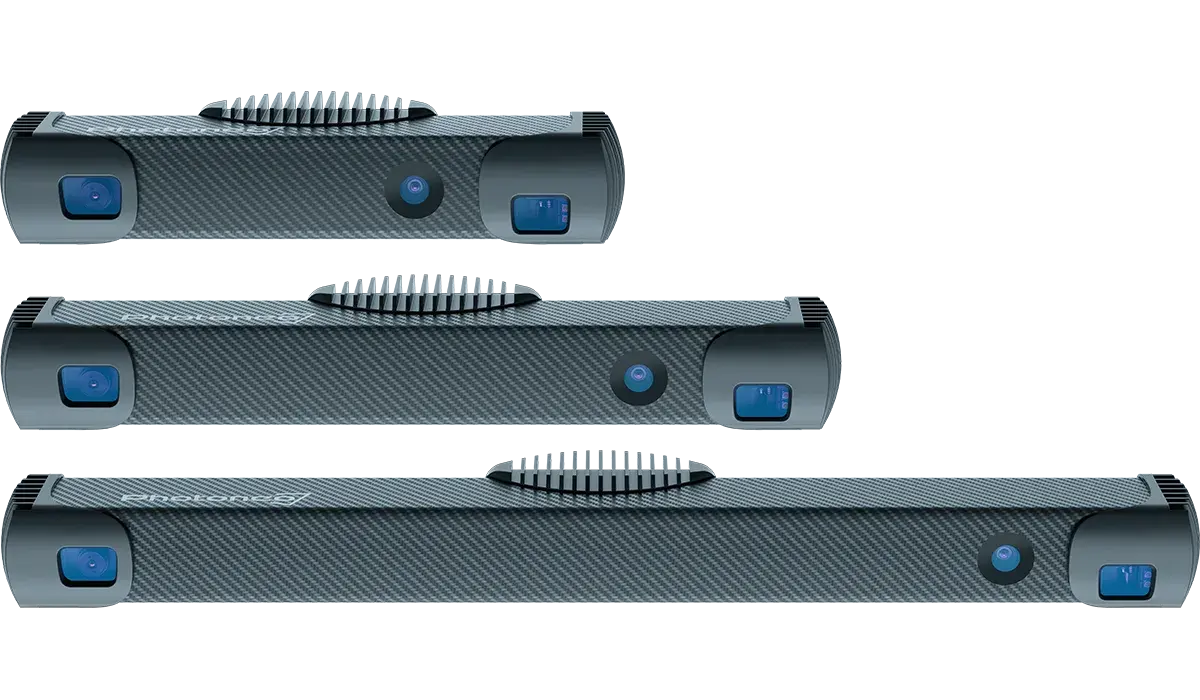

3D Sensors for High-Precision Automotive Assembly

MotionCam-3D

The only 3D sensor that delivers submillimeter accuracy at 20 fps—even on moving objects. Its patented parallel structured light technology enables real-time, high-resolution scanning without halting production lines.

- 3D scanning of objects moving up to 90mph (144 km/h)

- Real-time inspection of gaps, welds, fasteners

- Reduces cycle times by up to 2 seconds per operation

- In-line quality control of moving components

- Robotic guidance and hand-eye coordination

PhoXi 3D Scanner

The benchmark for scanning large automotive parts, PhoXi offers up to 0,035 mm accuracy with excellent ambient light suppression—ideal for demanding bin-picking applications, underbody components, weld inspection, and final assembly in dynamic environments.

- Scans up to 4 meters in harsh conditions

- Unaffected by welding arcs or sunlight

- Onboard computing for up to 50% faster processing

- Built for industrial environment

Recognize even the most complex objects

Maintain accuracy and reliability in the toughest environments. From hot metals to shiny metallic surfaces, you get clean, detailed scans where traditional systems fail.

Precisely scan polished parts, glossy materials with minimal interreflections.

Click and drag the image to inspect the interactive model: 3D scan of car engine.

From the smallest parts to entire chassis

The scanning volume of the MotionCam-3D and PhoXi 3D Scanner product lines ranges from 15 cm up to 4 meters, allowing you to scan large as well as very small objects.

Click and drag the image to inspect the interactive model: 3D scan of scratched and battered car door from 3,5 m / 11,5 ft

Vision Guided Robotics in Car Manufacturing

Enable robots to recognize and adapt to variance in car parts. From chassis to components, our 3D Sensors, Vision-Guided Software and Digital Twinning Software ensure accurate pickup and placement anywhere on the line.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Download Free E-Book

The Role of 3D Vision in Automotive Manufacturing

Discover how to achieve higher throughput, better quality, and lower integration complexity for high-mix, high-speed automotive production environments.

Download Free E-Book

The Role of 3D Vision in Automotive Manufacturing

Discover how to achieve higher throughput, better quality, and lower integration complexity for high-mix, high-speed automotive production environments.

3D Vision Guided Robotic Software for Smart, Dynamic Automation

Software

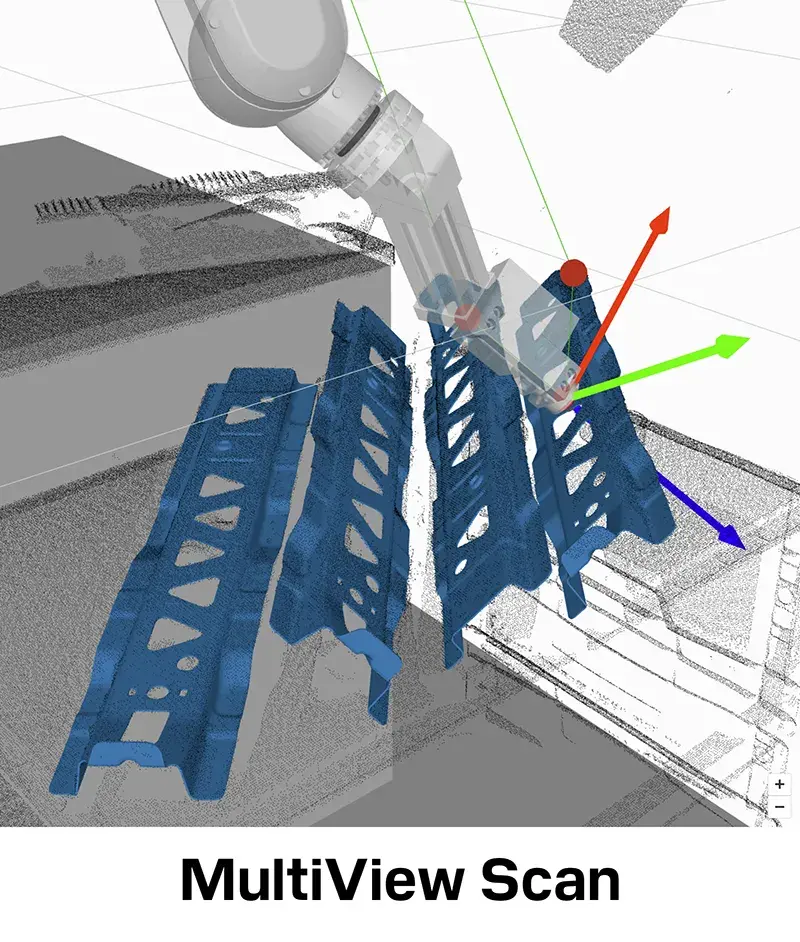

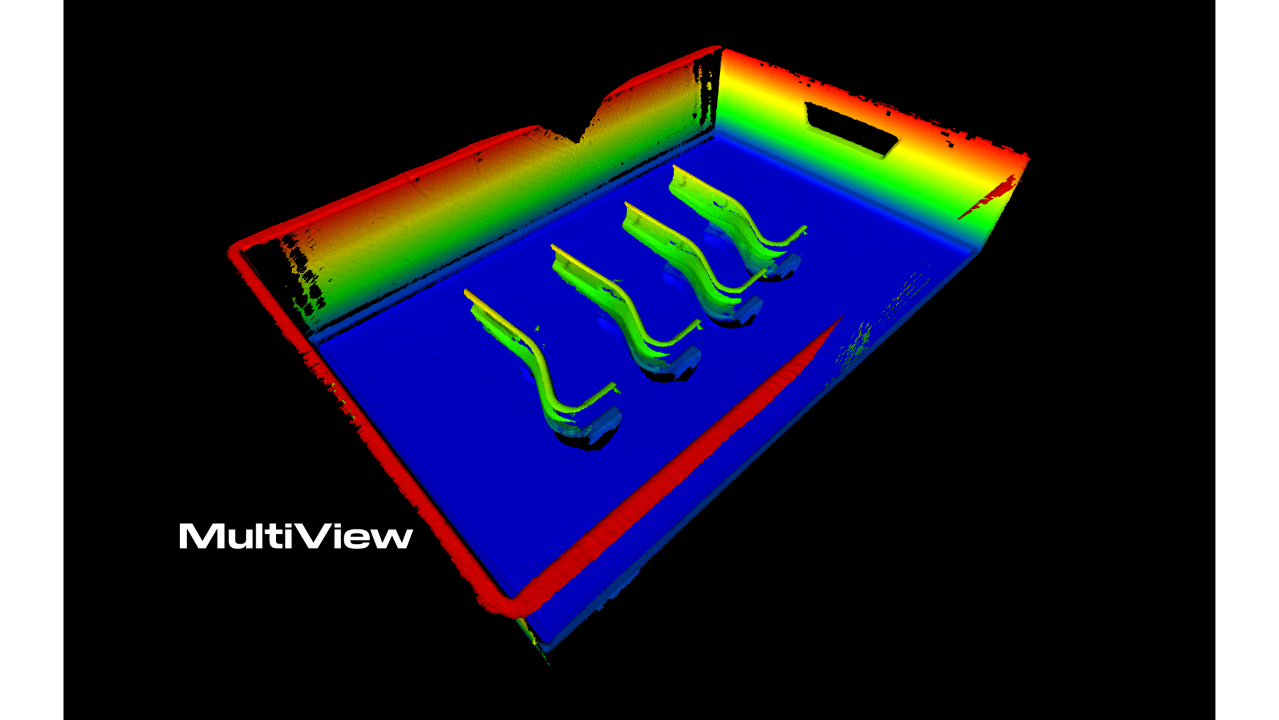

Complete 3D Data Capture for Complex Automotive Components with MultiView Scanning

In automotive manufacturing, no detail can be missed. MultiView Scanning ensures complete 3D data capture for even the most challenging parts — enabling faster, more accurate robotic handling, reducing cycle times, and improving first-pass yield across your production lines.

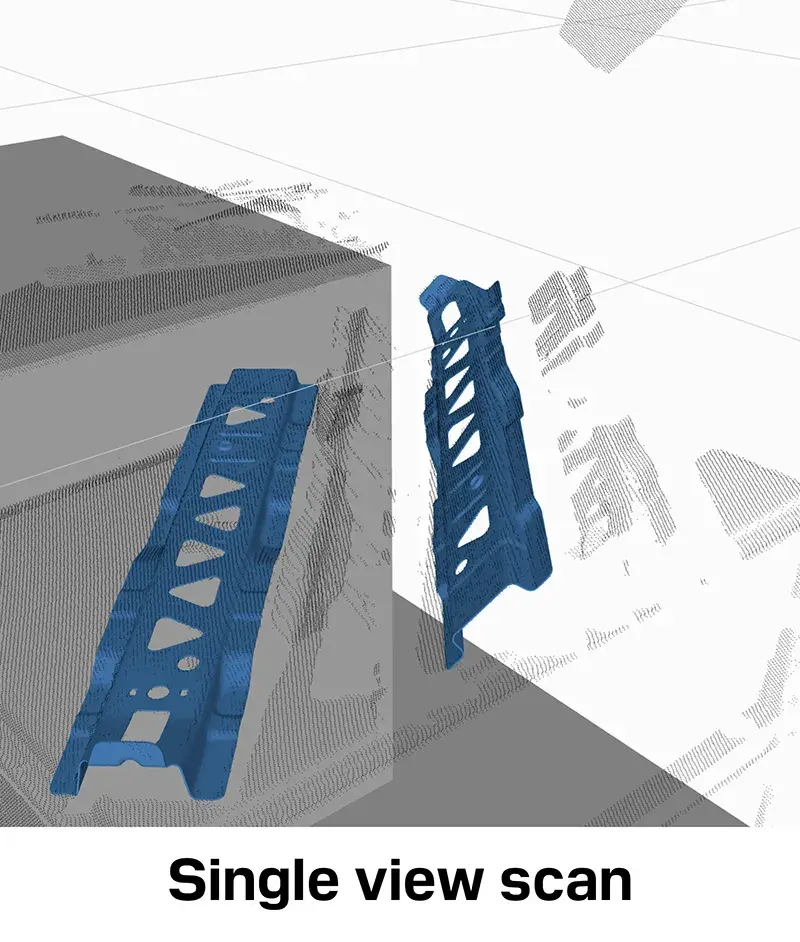

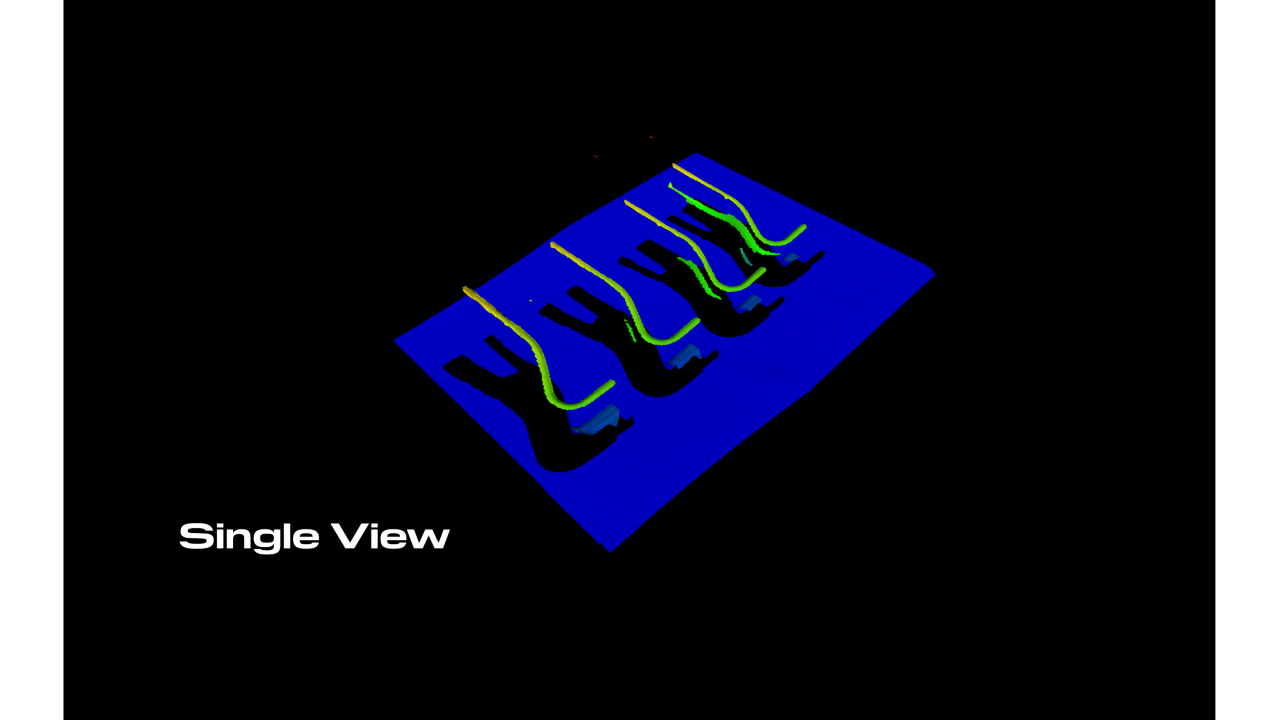

No Part Too Complex: Complete 3D Scanning with MultiView

Boost 3D data completeness for demanding tasks like bin picking, delayering, and digital twin creation. MultiView overcomes challenges with thin, reflective, or irregular parts, ensuring better grasp points, faster cycle times, and higher robotic success rates.

How MultiView Solves Scanning Challenges for Complex and Reflective Parts

By combining multiple scan perspectives, MultiView improves visibility, reduces occlusions, and ensures accurate recognition — even for challenging automotive components like thin metal sheets, reflective surfaces, and self-occluding shapes.

Why is it a game-changer?

- Capture Complex Shapes with Confidence

Easily scan thin, C- or L-shaped metal parts, and components stored in bins with compartments — even those too challenging for single-view systems. - Reveal Hidden Features for Precise Grasping and Assembly

Uncover critical features that might be missed in a single scan, ensuring precise localization and reliable robotic picking or placement. - Overcome Self-Occlusion Challenges

Accurately capture parts that block their own features, minimizing missed detections and boosting pick success rates. - Scan Larger Objects Without Compromising Detail

Seamlessly handle oversized parts that exceed a single field of view, maintaining full 3D data quality across the entire object. - Achieve Higher-Resolution 3D Data

Multi-capture scanning delivers finer detail and better point density, critical for high-precision tasks like bin picking, delayering, and digital twin creation.

How MultiView Works: Flexible Setups for Maximum Performance

MultiView scanning combines multiple perspectives to create a complete, high-detail 3D model of even the most challenging parts.

This can be achieved in two powerful ways:

MultiView: Dual-Scanner Setup

Use two strategically placed 3D scanners to capture different angles simultaneously, minimizing occlusions and capturing essential features that would otherwise be hidden.

By combining multiple angles into a unified, high-quality point cloud, MultiView ensures parts are correctly recognized, reliably picked, and perfectly positioned — even in the most demanding automotive environments.

MultiView: Hand-Eye Scanning with MotionCam-3D

For dynamic applications, MultiView uses a MotionCam-3D mounted on a robot arm to capture a continuous stream of high-resolution 3D data while the robot moves.

This setup is ideal for high-speed, high-mix tasks like picking thin, flexible items from bag racks, or scanning tightly packed, irregularly shaped automotive parts where single-view scanning would miss critical details.

Built for Automotive Automation: See Photoneo 3D Vision in Action

.png)

Award-Winning Innovation

for the Automotive Industry

Photoneo, now part of Zebra Technologies, has been at the forefront of automotive manufacturing innovation for over a decade. Born in Slovakia—the world’s largest car producer per capita—Photoneo draws from a deep talent pool of engineers and industry experts with firsthand automotive experience. This unique advantage fuels our ability to develop award-winning solutions tailored to the sector’s most demanding challenges.

How We Drive Automotive Innovation - Explore Our Free Resources

Watch On-Demand: Future of Automotive Manufacturing

Stream this 20 minute session to discover how 3D vision-guided robotics is transforming automotive manufacturing and unlocking new possibilities for intelligent automation.

%20(4).jpg)

Dynamic Assembly on Moving Production Lines

Discover how real-time 3D vision technology enables perfect fitment, faster changeovers, and flexible automotive assembly on moving lines.

Digital Twins in Automotive Manufacturing

See how digital twins combined with real-time 3D vision transform automotive manufacturing — boosting precision, flexibility, and efficiency.

Role of 3D Vision in Automotive Quality Control

Learn how next-gen 3D vision transforms automotive quality control — enabling real-time inspection, adaptive automation, and zero-defect production.