Free Download:

How Real-Time 3D Vision and Digital Twins Are Shaping the Future of Automotive Manufacturing

Download our free eBook and discover how combining live 3D scanning and digital twin technology empowers perfect fitment, adaptive automation, and higher production quality.

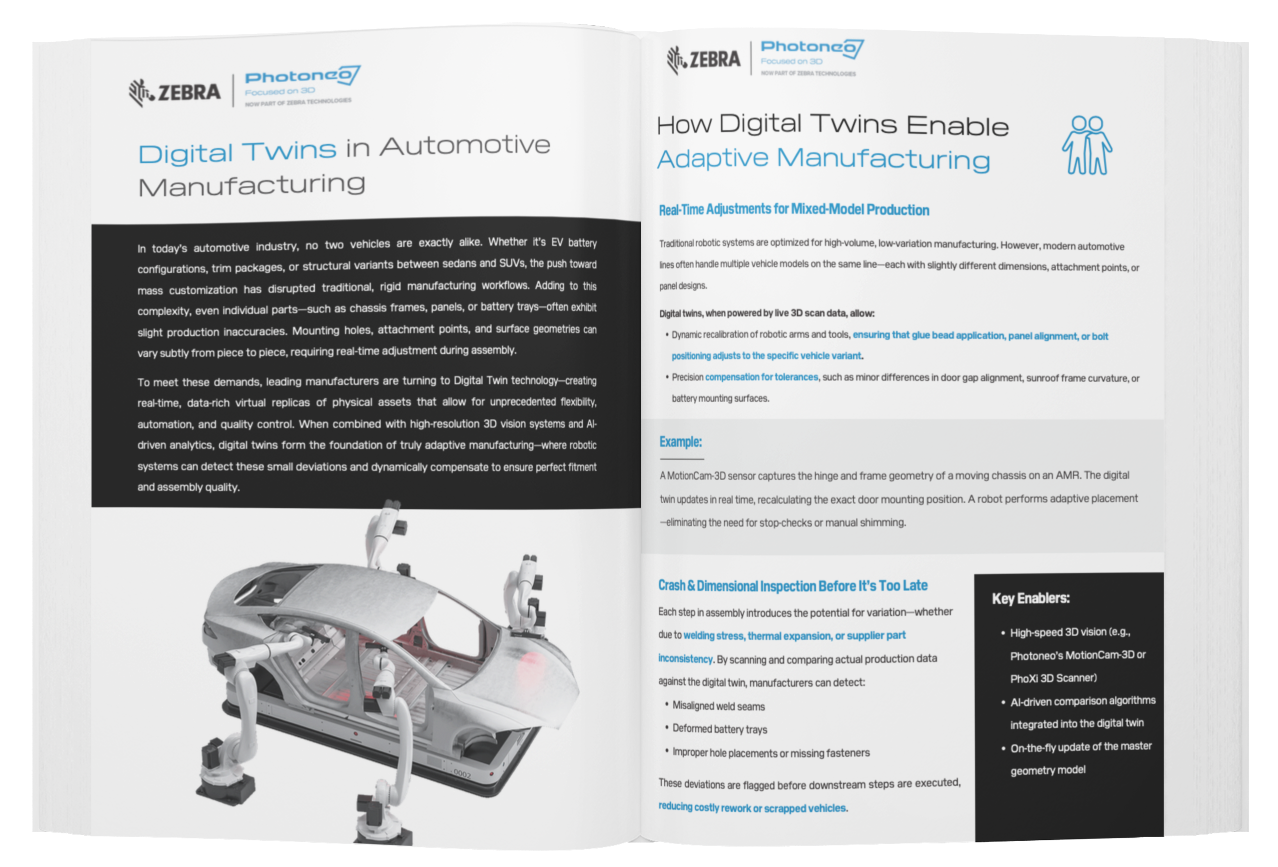

Adapt to Mass Customization Without Slowing Down

Modern automotive production demands flexibility. No two vehicles are identical — and rigid manufacturing workflows can’t keep pace.

In this eBook, discover how real-time 3D vision combined with digital twin technology enables dynamic, high-precision final assembly — even in fast-moving, mixed-model production lines.

Real-time robotic adaptation to part variations

Early detection of dimensional issues before costly rework

Seamless integration of 3D scan data with CAD/CAM systems

Digital traceability for quality control and compliance

What You’ll Learn Inside

The Shift from Static Production to Adaptive Manufacturing

Learn why static workflows fail modern mixed-model production — and how real-time digital twins solve it.

Real-Time 3D Vision: The Enabler of Dynamic Twins

Explore how Photoneo’s high-speed 3D vision systems fuel live updates, predictive analysis, and adaptive automation.

Applications Across Automotive Assembly

From dashboard mounting to door panel fitment — see how real-time adjustment ensures perfect placement, even on moving lines.

Key Benefits for Automotive Manufacturers

Higher quality, faster cycle times, seamless model changeovers, and full digital traceability.