Delayering

Whole-Layer Picking For Accelerated Logistics

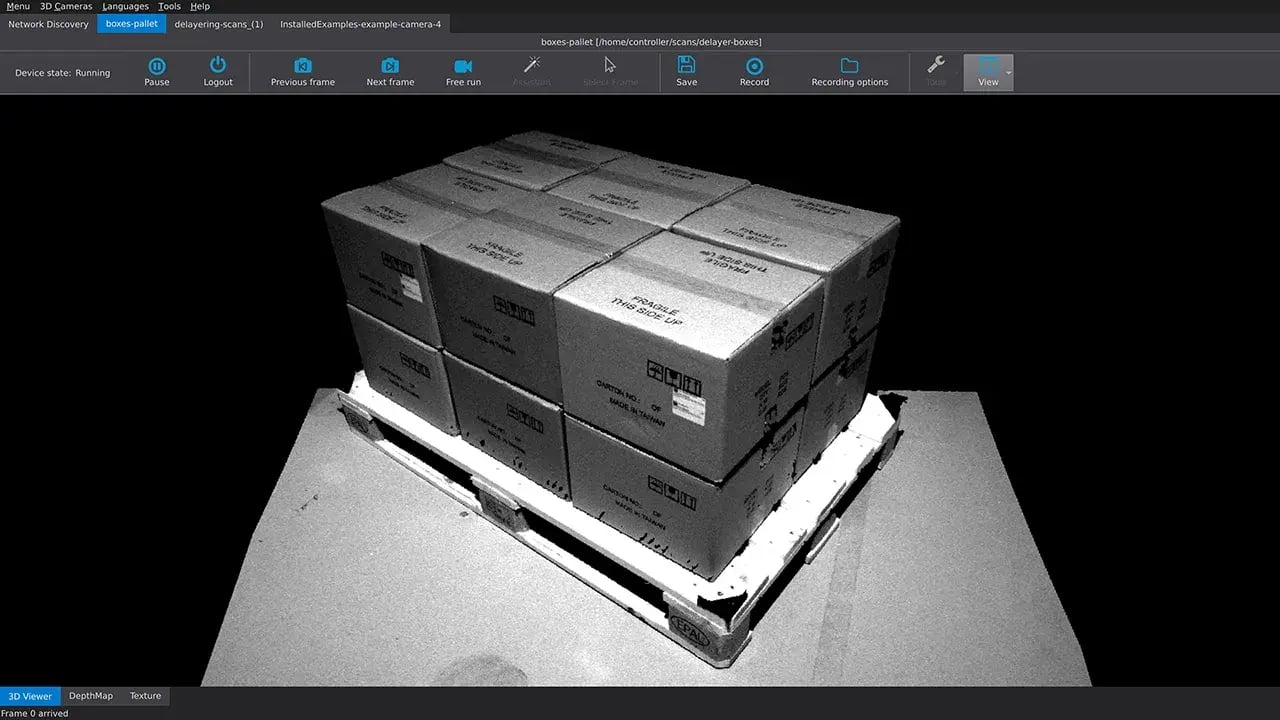

Randomly stacked products? Diverse goods? Multiple palette types? We merged advanced 3D vision with artificial intelligence to address nuanced intralogistics. Photoneo’s Depalletization solution tackles even the trickiest scenarios. Delayering software module automates robotic palette unloading and removes the entire layer of goods at once. Designed to handle diverse goods and pallet configurations, Delayering offers unmatched speed, flexibility, and ease of deployment.

Entire Layer - Single Action

Transform high-volume logistics, one layer at a time. Effortlessly offload single-SKU pallets at maximum speed.

Speed and Efficiency

Speed up the palette handling - pick whole layers instead of individual items. Photoneo's 3D vision technology accelerates the process with fast scanning and data processing.

Maximum Flexibility

Delayering handles a wide variety of goods, from boxes and bottles to cans and paper rolls (wrapped or unwrapped). Breaking down single-SKU pallets (e.g., a full pallet of the same product) for easy re-sorting and shipment.

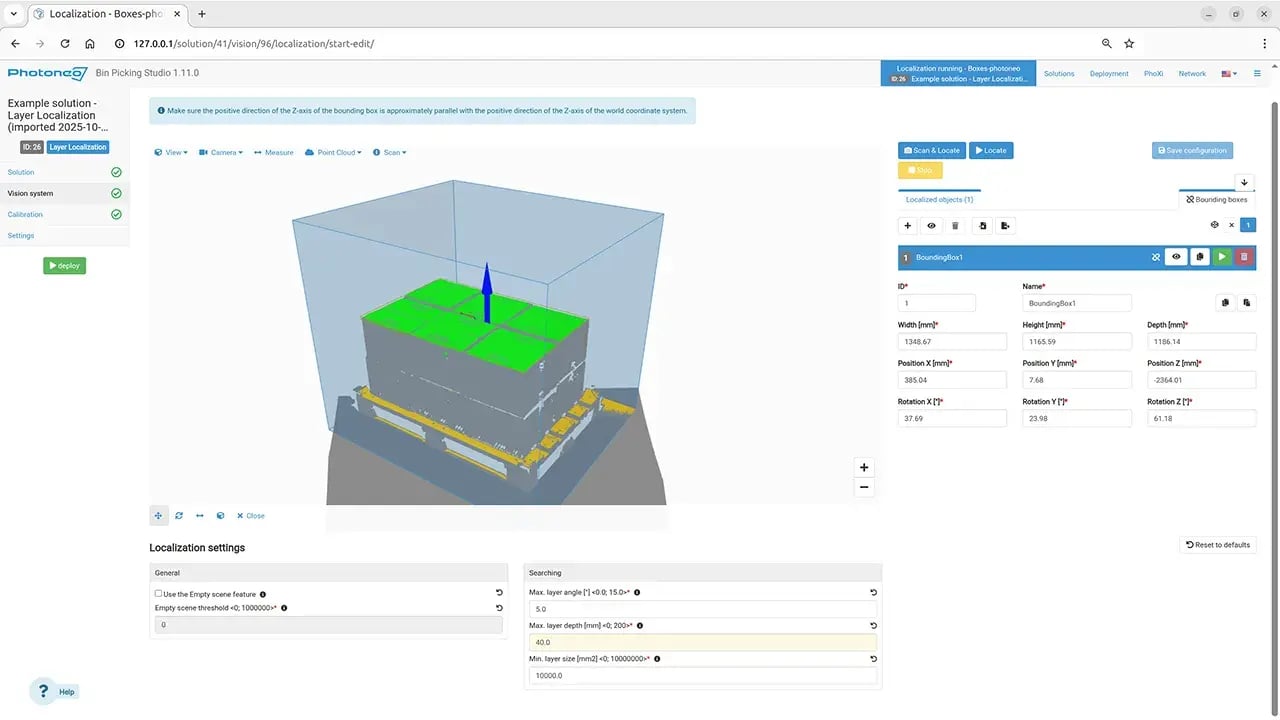

User-Defined Customization

Set up and use Delayering simply with an intuitive interface - no programming needed. Delayering is compatible with all major robotic systems and grippers, so it integrates easily into your existing operations.

Maximize Flow, Minimize Cost with Robotic Delayering

- Faster Order Fulfillment: Meet the increasing demands of the e-commerce and retail sectors. Reduced handling times ensure quicker deliveries.

- Increased Throughput: Handle higher volumes without compromising accuracy or reliability.

- Reduced Costs: Don’t waste the potential of your operators on mundane chores. Automating repetitive tasks minimizes dependency on manual labor.

- Lower Equipment Requirements: The ability to handle entire layers reduces the need for larger robotic systems, grippers, or additional equipment.

- Improved Accuracy: No damaged items, no disruptions. Precisely handle whole layers of diverse goods with inconsistent performance.

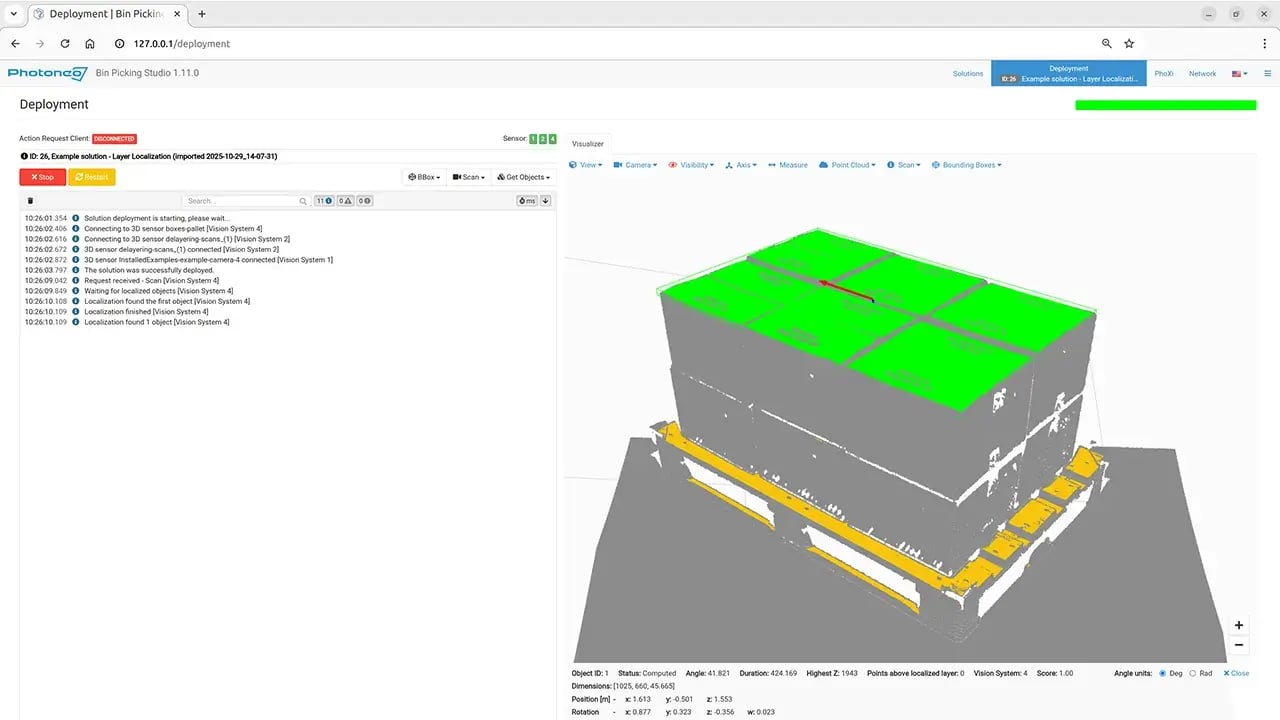

Inside Delayering Technology

The Intelligence Behind Flawless Unloading

Powered by advanced AI and high-resolution 3D vision, our delayering technology adapts in real-time to handle any load with precision and reliability.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

AI Neural Network

The system's AI-powered algorithms allow it to recognize various goods and pallet configurations, adapting to ensure consistent performance even with irregular or tightly packed items.

3D Vision Technology

Photoneo Sensors capture high-resolution scans of pallets, providing accurate data that ensures precise, intact layer removal by the robotic system.

Modular Integration

Delayering extends the functionality of Locator Studio, offering you a unified approach to robotic automation.